Hybrid Fluid Applied Roof Membranes (FARR) vs Coatings

Hybrid Fluid Applied Roof Membranes (FARR) vs Coatings

Coatings are flooding the roofing industry these days. It is rare to find a manufacturer or contractor that is not promoting a “roof coating” or “liquid membrane”. There IS a difference between a coating and a membrane, and it can be hard to draw the line at times.

It can be helpful to consider the human anatomy. Skin is a membrane. It’s tough, flexible, and virtually impermeable and it protects the underlying tissues and organs from the outside. However, skin can be damaged if its exposed to the sum too long.

Sunscreen is a coating. Its purpose is to protect skin – the membrane – from damage. It is permeable, so it’s still possible to sweat, and its applied relatively thin. It does not last very long, so it needs to be re-applied.

Liquid roofing products are not all that dissimilar.

There are those that work great as a coating (sunscreen): they are applied in thin layers of 20-30 mils (one mil equals one-thousandth of an inch), defend against UV degradation, are permeable, cool things down (thanks to their reflectiveness), but need t be re-coated and touched up often. They do not perform like a long-lasting membrane, but they are great at protecting membranes.

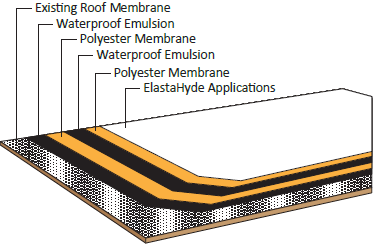

Then there are other liquid products that work great as a membrane: they are thick (50-130 mils), durable, flexible, strong, and impermeable. They serve as a primary barrier separating the structure from the elements. Some are reinforced, some are multi-layered, but the intended purpose is the same. They have no seams, adhere fully, and self-terminate. These liquid-applied, seamless membranes should act more like skin than sunscreen.

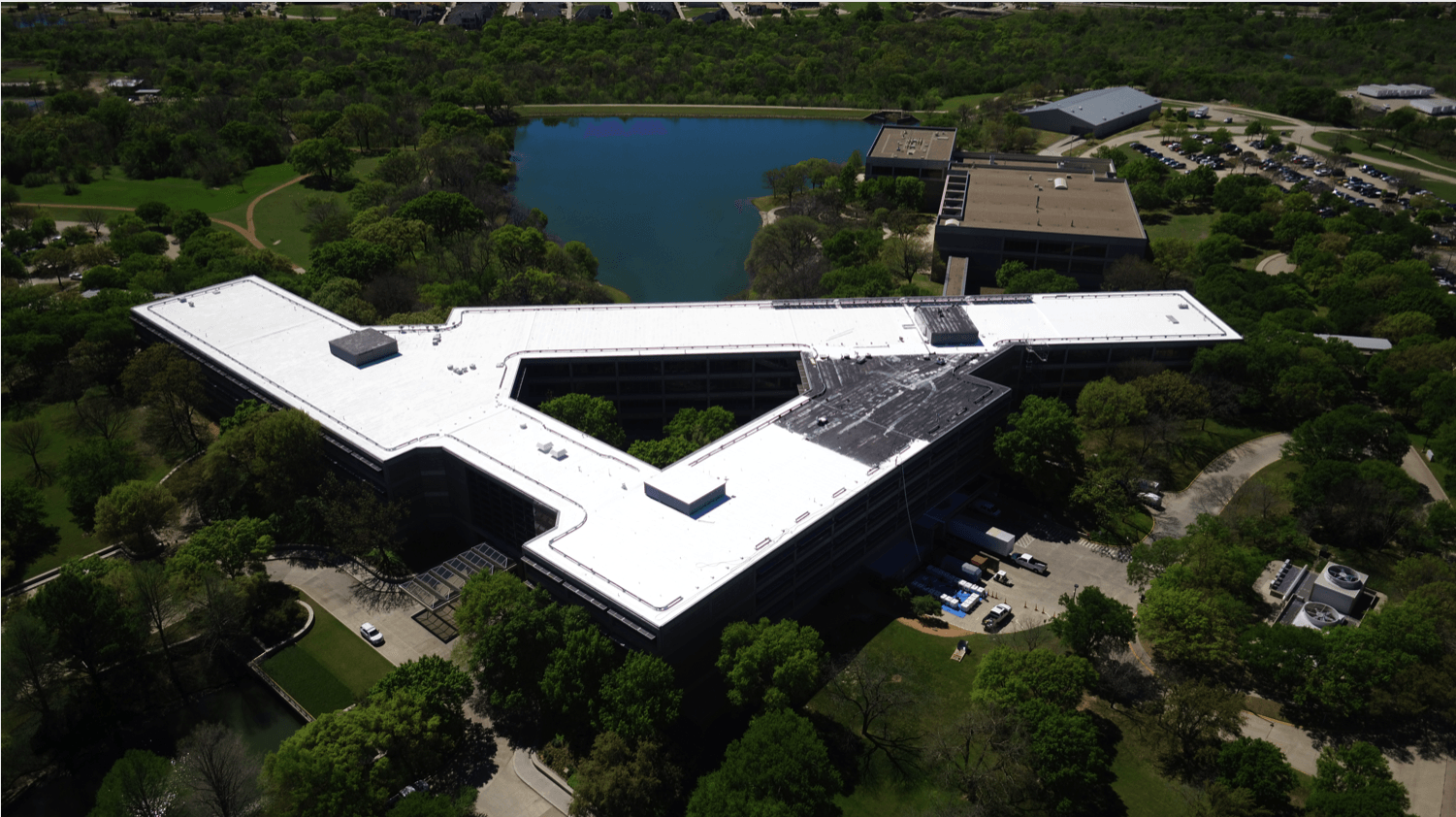

Installing a seamless membrane directly over an old roof helps maximize the original investment. However, it’s important to note that restorations or recovers are not recommended on roofs that are past a certain point of deterioration or have saturated insulation.

Liquid roofing membrane systems are best used for repairs, and/or the restoration of existing roof membranes to avoid costly, disruptive, and wasteful roof tear-offs. While they can be used in a full replacement or new construction, the focus of this article will be on their restorative capabilities.

Too often, liquid products are given the same negative stereotype. In Canada, extensive roof coating failures in the 1990’s made building owners leery of anything sold in a bucket or drum. Liquid roof technologies have improved drastically sine then, but each serves a very different purpose. Some liquids are better used as a coating and others as a membrane.

Here’s an overview of the applications of some of the most common liquid roof products :

Acrylic

Acrylic, by itself, is best used as a “sunscreen” for UV protection of membranes to extend their life. It’s great for reflectivity to reduce surface temperature and energy costs (depending on insulation in the existing roof). Other pros include that they’re low-cost, come in a variety of color options, serve as a good sacrificial wear layer and are easy to recoat. The cons. Cheaper varieties of acrylic liquid roofing products are just that. Unless they’re reinforced (like with a high quality polyester) they don’t withstand ponding water well, are inflexible, have low strength and in some cases have been inappropriately promoted as a membrane.

Silicone.

Silicone is best used as a topcoat over a membrane to prevent premature degradation, extend life, and add reflectivity . Other pros include that it’s reflective, withstands ponding water, resists animal fats, has good tensile strength and experiences minimal degradation. However, its exceedingly difficult to repair or recoat, as nothing but silicone will adhere to silicone. Other cons include that it is not water-based, picks up dirt (turns yellow/brown quickly), has poor tear resistance and is slippery when wet.

Polyurethane Foam Roofing Products

Polyurethane foam is best used as insulation material, not as a waterproofing membrane. Its topcoat is typically acrylic or silicone and requires constant maintenance to protect the foam from UV exposure. The pros of polyurethane foam are that it provides excellent insulation (it has a high R-value), can be applied to any thickness and is watertight. The cons of polyurethane foam are that it’s not UV stable, requires a top coat to protect it from becoming open-cell, is easily punctured and damaged by foot traffic, birds, and insects, is difficult to install, has no elongation and low strength.

Urethane Roofing Products

Urethane is best used as a membrane for parking decks, flooring, plaza decks, and other industrial applications. It’s suitable for use on certain types of existing roofs but is difficult to repair or recoat. The pros of urethane are that it’s strong and durable, impermeable and has high tensile strength. The cons of urethane are that its installation is sensitive, causes toxic fumes, is flammable in liquid form, can be expensive and has low elongation.

Liquid Rubber Roofing Products

Liquid rubber is best used as a roof restoration membrane with a reflective topcoat. The pros of liquid rubber are that it has high elongation, good tensile strength, can be applied in any thickness in one coat, is impermeable, has excellent adhesion and can be installed to membrane thickness. The cons of liquid rubber are that it only comes in one color (black), typically requires top coat, is more expensive and cannot be installed in freezing temperatures.

Hybrids

Hybrid systems are membranes that include many of the best qualities of coatings but in addition, because they contain multiple layers of waterproofing and are reinforced with high strength polyester, are a superior long lasting membrane. Unlike most other membrane systems that have to be torn off and replaced at the expiration of their useful life - hybrid systems by design, if properly maintained, can have their warranties extended indefinitely by simply replenishing the protective top layer of acrylic periodically.

In addition, they can usually be installed over any type of existing roof system (caution: substrate cannot have substantial damage including water saturation of insulation) and are fully code compliant being installed on facilities with two roofs already in place - without the need for a tear-off.

With many liquid technologies available to protect roof assets, it is important to choose the right product for the application. A new membrane many be needed, and a thin coating would only cause further problems. Or a new membrane may not be needed, only a coating to increase the roofs life. Never hesitate to ask contractors, consultants, or suppliers for physical material samples, independent lab tests reports, data sheets, contractor certifications, case studies, and references. Proper due diligence is vital when investing further in existing roof assets.

Monolithic Roofing Solutions MRS) is a certified dealer/installer of Western Colloid's hybrid seamless single-ply built up FARR (fluid applied reinforced roof) systems . To see if your roof would be a candidate for this exclusive roofing system, call us for a complimentary inspection and analysis.

“The Last Roof Your Building Will Ever Need!”

Monolithic Roofing Solutions 525 Industrial Blvd. Suite A, Grapevine Texas (469) 628-4441 www.monolithicroofingsolutions.com